Stainless Steel Pipe Welded Roll Forming Machine/ Machine to Make Square Tube

Description

Basic Info

| After-sales Service | Online Support, Free Spare Parts |

| Warranty | 12 Months |

| Pipe Material | Carbon Steel |

| Condition | New |

| Customized | Customized |

| Theory | Pipe Welding Producing Line |

| Application | Industry, Decoration |

| Type | Pipe Production Line |

| Transport Package | Nude, with Waterproof Cloth and Stow-Wood. Importe |

| Specification | 45Mtr x 2Mtr x 2Mtr |

| Origin | China |

| HS Code | 84552210 |

| Production Capacity | 3sets/Month |

Product Description

Stainless Steel Pipe Welded Roll Forming Machine, Machine To Make Square TubeThe production line adopts advanced pass technology, PLC automatic control system, with stable operation,convenient operation and repair, and reached the advanced level in the same industry in the structure and accuracy.Equipment from the material to tube run out, the speed adjusts according to the tube specification changing.

Production Capacity:

| No. | Item | Numerical value |

| 1 | Round pipe outside diameter | Φ12.7mm~Φ128mm |

| 2 | Round pipe thickness | 0.5~3mm |

| 3 | Square tube size | 10 x 10mm~100 x100mm |

| 4 | Square tube thickness | 0.5~3mm |

| 5 | Rectangular tube size | 10x50mm ~10x100m |

| 6 | Rectangular tube thickness | 0.5~3mm |

| 7 | Produce speed | 20M/min~100M/min Size smaller the speed faster, size bigger the speed lower |

| 8 | pipe length | 4M ~ 10M |

| 9 | pipe glancing flatness | ≤1mm(1M pipe length) |

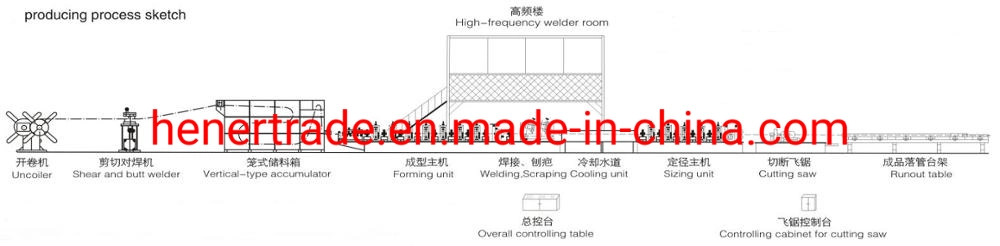

Working Flow:

Raw material (steel strip coil) →uncoiling→shear and butt-welder→material accumulating→passively leveling→forming machine→high frequency welding →remove the burrs outside→cooling →sizing machine→straightening→fixed length cutting →run out table→finished tube

Uncoiler is the important equipment in steel pipe making line, it's function is to support and expand the strip coil, so strip can enter intomachine for roll forming. Strip coil can be expanded by hydraulic and uncoiler can be rotated forward and reverse. Strip expanding speedcan be adjusted, braking device designed with pneumatic cylinder to press the brake rubber block, safety and reliable

| No | Structure type | Double head type |

| 1 | Coil expanding method | Pneumatic or hydraulic expending |

| 2 | Inner diameter of steel coil | Φ450mm~Φ550mm |

| 3 | Outer diameter of steel coil | Φ1000mm~Φ1600mm |

| 4 | Width of steel coil | H40 ~128mm |

| 5 | Weight of steel coil | Maximum 1.6 Ton for each side |

| 6 | Brake type | Pneumatic disc brake |

2.Auto Shear and butt-welding machine

It"s function is shearing the head and the end of the steel strip, cutting of the irregular part then welding two steel strip together,Polishing the welding seam,enter into the accumulator,so the line can working continuous.

| No. | Item | numerical value |

| 1 | Thickness of steel strip | 0.5~3mm |

| 2 | Width of steel strip | 40~120mm |

| 3 | Shear method | Pneumatic shear |

| 4 | Frequency converter | Delta |

| 5 | welding method | Auto welding |

| 6 | Welding machine | Argon arc welding machine |

3.Vertical type accumulator

4.Forming Machine:

The function of this part is to make the steel strip become to the tube blank by forming rollers

| Parts name | parameter | remark | |

| Flattening unit | 1. Flattening roll quantity | Seven piece | |

| 2. Frame roll material | 40Cr | ||

| Horizontal roll stand | 1.group amount | Eight group | |

| 2.frame material | Steel forging | ||

| 3.Diameter of horizontal roll shaft | Φ55mm | ||

| 4.Material of horizontal roll shaft | 42CrMo | HF quenching 60HRC±2 | |

| Vertical roll seat | 1.group amount | Eight group | |

| 2.vertical roll seat material | QT150 | ||

| 3.diameter of vertical roll shaft | 35MM | ||

| 4.vertical roll material | 42CrMo | HF quenching 60HRC±2 | |

| Gear box | 1.group amount | Eight group | |

| 2.box structure | weld assembly | HF quenching and shot blasting | |

| 3.structure | Spiral bevel gear transmission | ||

| 4.spiral bevel gear material | 20CrMnTi | Forging and gear quenching | |

| 5.gear shaft material | 40Cr | Tempering and quenching | |

| Power transmission structure | Universal shaft transmit to horizontal shaft(16pieces) | ||

5.Welding seam guiding,extruding,scarfing,scarfing rewinder.

The Function of this part is to aligning the welding seam and guideing the tube blank to extruding device ,so the weldingseam will be closed before welding,Use planer tool to remove the welding burrs to insure the welding surface is smooth.

| No | Parameter | Remark | |

| 1 | SG structure | Design like TH, 360 degree rotating | One set |

| 2 | SG shaft diameter | 30mm | |

| 3 | SG shaft material | 42CrMo | |

| 4 | SQ device structure | Two roll or three roll extruding type | One set |

| 5 | SQ shaft diameter | 35mm | |

| 6 | SQ shaft material | 42CrMo | |

| 7 | Welding seam scarfing | Two sets | |

| 8 | Welding seam cutter | Feed and back by air cylinder | |

| 9 | Cutter fine adjustment | Manual adjust the lead screw | |

| 10 | Scarfing rewinder | Insulation design | One set |

| 11 | Scarfing rewinder type | Kick out burrs by air cylinder | |

| 12 | Grinding roll stand | One set |

6.Water tank:adopt water thank spraying type to make sure the tube blank is cooling enough.

Cooling method:All pipe body immerse in water

7.Sizing machine:

The function of this part is used to finishing the tube blank from the forming machine,so the tube size can meet the physical dimensioncustomer required.

| Parts name | parameter | remark | |

| Horizontal roll stand | 1.group amount | Six group | |

| 2.portal frame material | Steel forging | ||

| 3.diameter of horizontal roll shaft | 55mm | ||

| 4.material of horizontal roll shaft | 42CrMo | Heat treatment 60HRC +_2 | |

| Vertical roll seat | 1.group amount | Six group | |

| 2.vertical seat material | QT 50 | ||

| 3.diameter of vertival roll shaft | 35MM | ||

| 4.material of vertival roll shaft | 42CrMo | Heat treatment 60HRC +_2 | |

| Gear box | 1.group amount | six group | |

| 2.box structure | weld assembly | HF quenching and shot blasting | |

| 3.structure | spiral bevel gear transmission | ||

| 4.spiral bevel gear material | 20CrMnTi | Forging and gear quenching | |

| 5.gear shaft material | 40Cr | Tempering and quenching | |

| Power transmission structure | Universal shaft transmission to the shaf(12 pcs) | ||

Cold Saw:

It is cold cutting saw,pipe end is smooth and non-distortion.the length of burrs after cutting is lower than 0.2mm,Leave out the process of chamfering,no need chamffering machine, it will also reduce the cost in the future,low rotation speed with deep feeding,

Saw blade with a low speed ,so it won"t damage worker when saw blade is broken when producing,the noisy is small, Design saw bladeback quickly when emergency stop or suddenly power off. So saw blade will not broken.

| No. | Structure | Cold cutting saw |

| 1 | Maximum diameter | 41(16x49)mm |

| 2 | Maximum thickness | 1.8mm |

| 3 | Cutting length and precision | L=4~8≤±2mm |

| 4 | Electric control system | Yaskawa |

| 5 | Size of saw blade | 350mm |

| 6 | Material of saw blade | HSS |

| 7 | Driving motor | YASKAWA Servo motor 11KW |

| 8 | Cutting motor | Siemens AC motor 7.5kw |

| 9 | Feeding motor | YASKAWA Servo motor 1.8KW |

| 10 | Speed of cutting | Maximum 100M/min |

Pipe Making Rollers

Pipes

ExhibitionFactory PhotosWhy choose Us?

- We have sold more than 3000 sets roll forming machines to many countries around the world.

- We have hundreds of models about all kinds of roll forming machine for your reference, you could't worry

- if you don't have a profile drawing.We can recommond you some classical models that is common in your country.

- When designing the machine, our considerate service will estimate and avoid the problem that may happen.

- One set machine can provide many solutions with different price level.But they are all the cost-effective.

- We attach importance to many details. Every machine part quality is higher than our competitors in same price level.

Prev: Wholesale Arcade Game Machine Crazy Toy 2 Crane Claw Machine for Sale

Next: Coin Pusher Game Toy Story Toy Vending Machine Arcade Claw Machine

Our Contact